In the fast-paced world of electronics, staying ahead requires continuous improvement and adaptation. One critical area where advancements can significantly influence outcomes is in the Printed Circuit Board (PCB) manufacturing process. Upgrading production lines not only boosts efficiency but also ensures higher quality products and faster delivery times.

1. The Importance of Modernizing PCB Production Lines

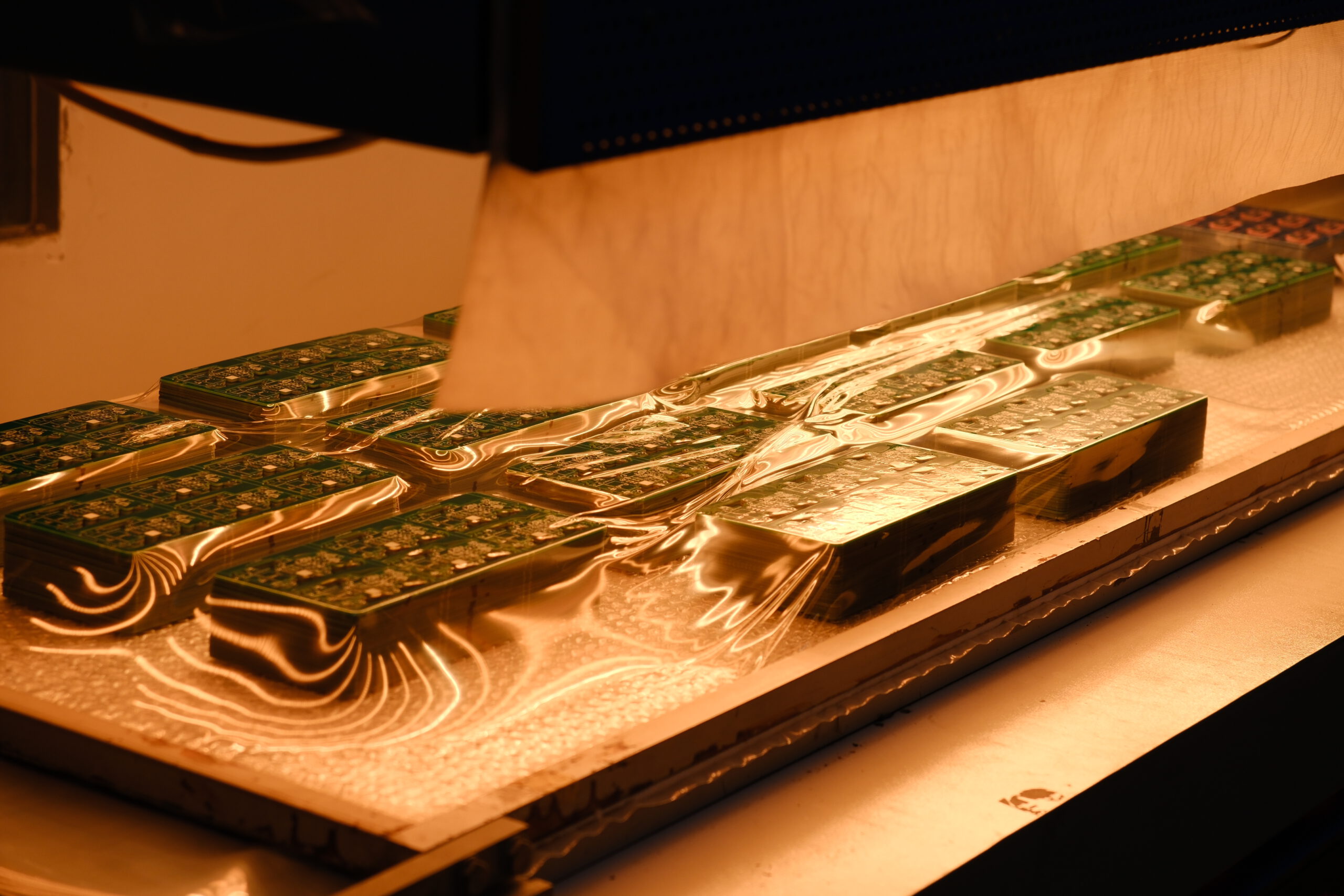

As technology evolves, the demand for more complex and reliable PCBs increases. Manufacturers that invest in modern equipment and streamlined processes are better positioned to meet these demands. Upgrades such as advanced pick-and-place machines, automated soldering stations, and enhanced quality inspection systems play a pivotal role in achieving these goals.

2. Benefits of Production Line Upgrades

-

Faster Turnaround Times: Implementing state-of-the-art machinery reduces production bottlenecks, allowing for quicker assembly and delivery of PCBs.

-

Improved Product Quality: Advanced equipment ensures precise component placement and soldering, leading to more reliable and durable PCBs.

-

Increased Production Capacity: Modern production lines can handle higher volumes, enabling manufacturers to fulfill larger orders without compromising on quality.

-

Enhanced Flexibility: Upgraded systems can adapt to various PCB designs and complexities, accommodating a broader range of customer requirements.

3. Commitment to Excellence in PCB Manufacturing

By focusing on continuous improvement and embracing technological advancements, PCB manufacturers demonstrate a commitment to delivering superior products. These efforts not only enhance operational efficiency but also build trust and satisfaction among clients seeking reliable and timely PCB solutions.

For more information on our PCB manufacturing capabilities and how we can support your projects, please contact us.

Share this article

Written by : bs.pcb

Follow us

A quick overview of the topics covered in this article.