2025 Trends in PCB Design for AI, IoT, and Edge Devices

From smart glasses and wearables to AI accelerators and edge computing gateways, the demand for compact, high-performance PCBs is reaching new heights in 2025. As devices become smarter and smaller, engineers are pushing the limits of PCB design.

In this article, we explore the key PCB trends driving the next wave of innovation — and how BaiShun PCB is helping hardware creators build what’s next.

1. Smaller Form Factor, Higher Layer Count

Modern AI and IoT devices demand more functionality in less space. As a result, designers are moving to:

-

📐 10+ layer stack-ups

-

🧠 Fine-pitch BGA layouts

-

🧲 High-speed signal routing within tight spaces

BaiShun PCB supports up to 32 layers, trace/space as fine as 2.5 mil, and 0.15 mm BGA pads, making it ideal for complex system-on-chip (SoC) and AI modules.

2. High-Frequency & High-Speed Performance

With edge AI devices using GHz-level processors and wireless modules, managing impedance and EMI is now a core part of PCB layout.

In 2025, expect to see:

-

🔍 Controlled impedance stack-ups

-

📶 RF shielding zones for WiFi/5G/LoRa

-

🧾 Use of low-loss materials like Rogers or Taconic

At BaiShun, we support impedance tolerance to ±7.5%, with full support for RF board design and impedance simulation on request.

3. Flex and Rigid-Flex PCB Integration

Wearables, foldables, and portable AI-powered gadgets demand flexibility. In 2025, many designs are shifting toward:

-

📱 Rigid-flex PCB layouts

-

🧵 Embedded sensors within flexible circuits

-

🔄 Multi-function layers that fold or bend

BaiShun manufactures both standard rigid and flex/rigid-flex PCBs, giving product developers more room to innovate with space-saving designs.

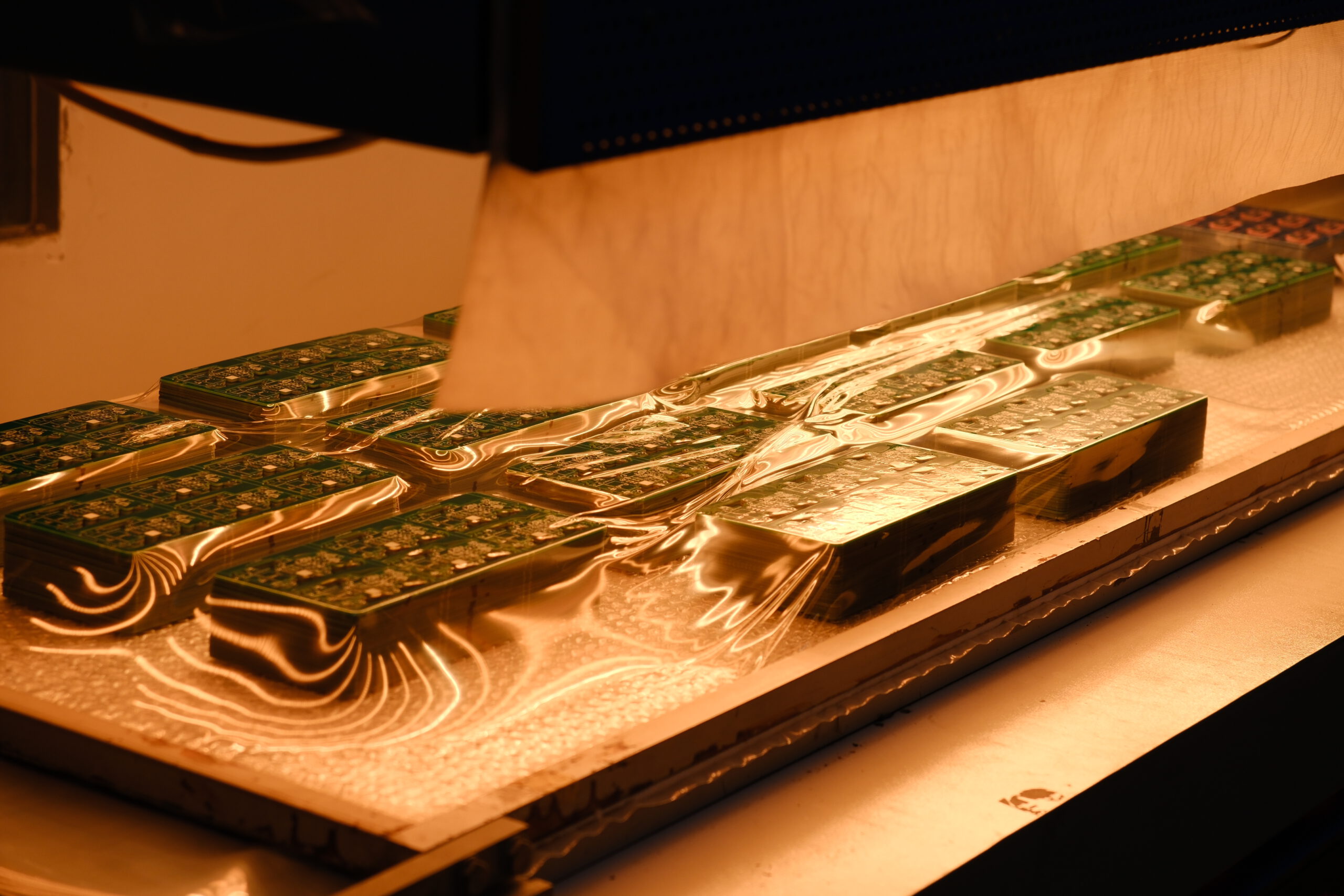

4. Thermal & Power Management for Edge AI

Edge devices with real-time processing (AI cameras, autonomous drones, etc.) consume more power and generate more heat. This drives demand for:

-

🔥 Heavy copper PCBs (up to 6oz)

-

🌡️ Thermal vias and heat sinks integrated in layout

-

⚡ Dedicated power planes in multilayer stack-ups

With BaiShun’s high copper capability and tight drill/pad tolerances, your design can stay cool — even under heavy edge workloads.

5. Faster Prototyping, Tighter Product Cycles

In the AI + IoT world, time-to-market is everything. Startups and OEMs need:

-

⚡ Rapid prototyping

-

🔁 Small batch production to test iterations

-

🌎 Scalable manufacturing once market fit is achieved

BaiShun PCB supports this flow by offering direct-to-factory quotes, DFM support, and the ability to scale from 50 to 50,000+ boards.

✅ How BaiShun PCB Supports Next-Gen Hardware

BaiShun isn’t just a board factory — we’re a strategic manufacturing partner for innovators in AI, edge computing, and IoT.

With:

-

✅ ISO 9001 / 14001 and UL certification

-

✅ In-house surface finishing (ENIG, OSP, HASL, Immersion Tin)

-

✅ Flying probe and full E-test for every board

-

✅ Advanced stack-up design and engineering support

We help you take your idea from prototype to product — reliably, affordably, and fast.

🚀 Conclusion

As the hardware world embraces smarter, faster, and smaller devices, the PCB is more critical than ever. In 2025, success depends on precision engineering, advanced materials, and agile manufacturing.

At BaiShun PCB, we’re ready to build the boards that power tomorrow’s AI and IoT breakthroughs.

📎 Need a quote for your AI or edge device PCB?

👉 [Upload your Gerber files now] or email us at hello@jxbsdlkj.com

Share this article

Written by : bs.pcb

Follow us

A quick overview of the topics covered in this article.