PCB Factory vs Broker: Why Hardware Startups Should Go Direct

Whether you’re prototyping a smart device, building a custom sensor board, or scaling your AI-powered product — getting the right PCB partner can make or break your hardware timeline.

While PCB brokers may offer convenience, working directly with a certified, experienced PCB factory like BaiShun PCB gives you a competitive edge in terms of cost, control, speed, and reliability — all critical for lean hardware startups.

1. What’s the Difference Between a PCB Broker and a PCB Factory?

-

PCB Broker = A middleman who takes your files and outsources the job to a third-party manufacturer. They rarely own production lines.

-

PCB Factory = A real manufacturer with in-house equipment, engineering teams, and full process control.

In short:

Brokers resell — factories build.

2. Why Startups Should Avoid Brokers

Startups often need speed, transparency, and technical flexibility. Brokers introduce risk:

| Problem with Brokers | Impact on Startups |

|---|---|

| ❌ No control over production | Delays, reworks, or miscommunications |

| ❌ Hidden markups | Higher cost per board with no added value |

| ❌ Inconsistent quality | No guarantee which factory gets your Gerber file |

| ❌ Slower revisions | Every change passes through another layer |

Startups move fast — and brokers slow you down.

3. Benefits of Working Directly with BaiShun PCB

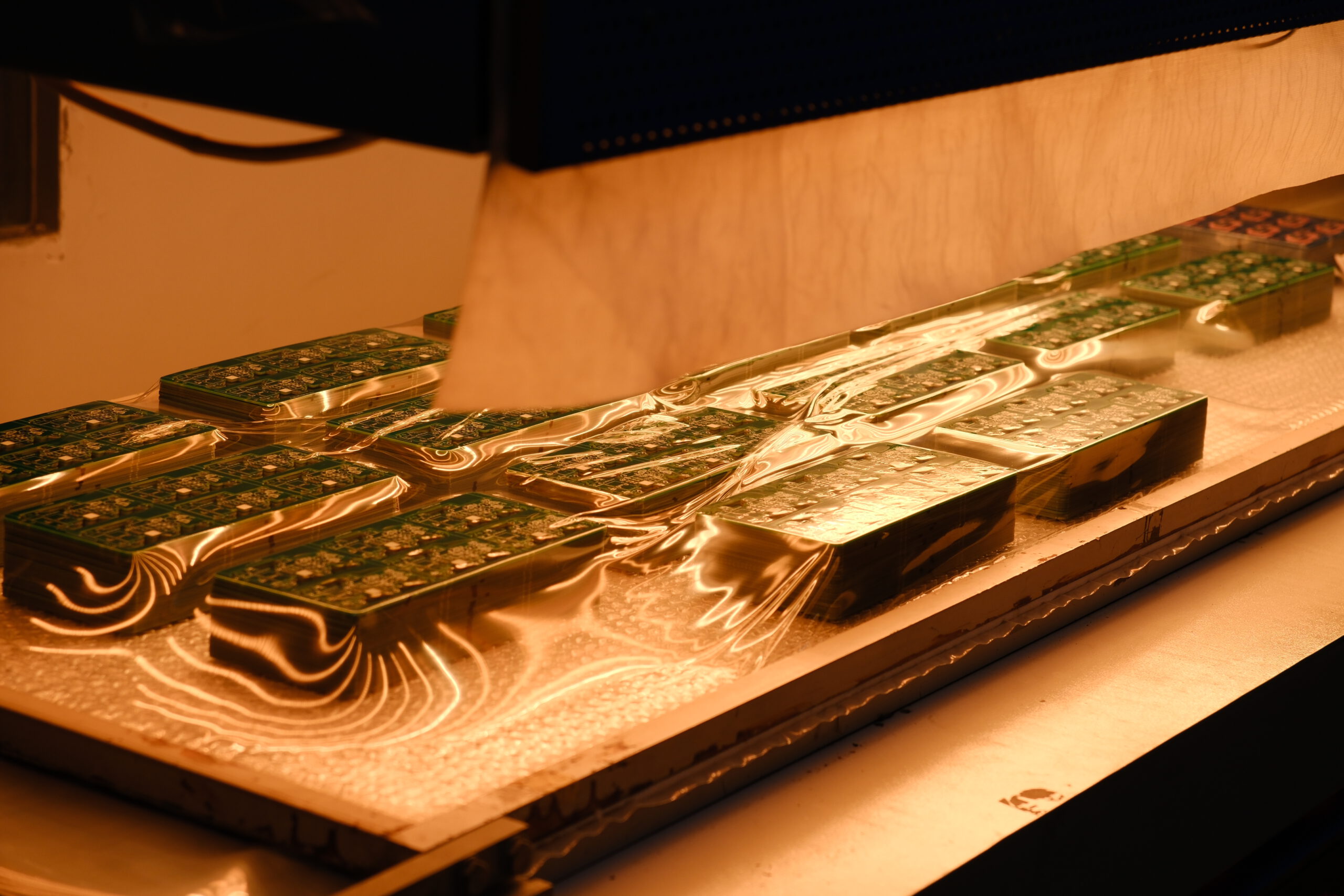

At BaiShun PCB, you work with a real, certified PCB manufacturer in China with over 800,000 m² annual capacity and a full in-house setup. Here’s how we support startups:

✅ Transparent Pricing

Get quotes directly from our factory — no markup, no middleman. This means more accurate forecasting for your BOM and manufacturing budgets.

✅ Faster Turnaround

Our optimized workflows allow for rapid prototyping and short-run production with real-time engineering support.

✅ Engineering Support

Our 400+ team includes engineers who help with DFM feedback, material advice, stack-up planning, and Gerber checks — all before production begins.

✅ Factory-Level QC

We follow IPC Class 2/3, use UL-certified materials, and test every board with flying probe or E-test. You can even request production photos and QA reports.

✅ Flexibility for Scaling

Start with 50 boards, grow to 5,000 — we adapt as you grow, offering the same quality at every stage.

4. When Brokers Might Still Make Sense

To be fair — brokers can help with:

-

🧳 International language barriers

-

🧩 Very low-volume, non-urgent hobby projects

-

🧾 Consolidating multiple suppliers (at a premium)

But for product teams building real businesses, direct factory access = strategic advantage.

5. How to Work with BaiShun PCB

Ready to go direct?

Here’s how the process works:

-

📨 Send us your Gerber files (ZIP format)

-

🔎 We run a free DFM check

-

💬 You receive a quote within 24–48 hours

-

🛠️ We manufacture and ship globally — fast.

You can also request:

-

📐 Stack-up templates

-

🧪 Material datasheets (FR4, polyimide, high-Tg, etc.)

-

📦 Prototyping + production combo packages

✅ Conclusion

Hardware startups deserve full control over their product — and that starts with the PCB. Skip the markup and the guesswork. Work directly with a proven PCB factory that supports you from first prototype to global scale.

📎 Ready to get your quote?

👉 [Upload Your Gerber Files] or email: hello@jxbsdlkj.com

Share this article

Written by : bs.pcb

Follow us

A quick overview of the topics covered in this article.