Driving Innovation: BaiShun PCB’s Role in the Automotive Industry

As vehicles evolve into smarter, more connected systems, the demand for high-reliability, precision-engineered PCBs in the automotive sector has surged. From EV battery management systems to ADAS sensors and vehicle control units, printed circuit boards are now critical components in modern automotive design.

At BaiShun PCB, we help global automotive innovators bring their electronics to life — with factory-direct production, automotive-grade quality, and rapid global delivery.

1. The Rise of Electronics in Modern Vehicles

Over 50% of the cost of modern vehicles comes from electronics — and that number keeps rising. PCBs are used in nearly every automotive function:

-

🧠 Vehicle Control Units (VCU)

-

🔋 EV DC-DC converters and BMS systems

-

🎯 Sensors for ADAS, airbags, and tire pressure

-

💡 LED lighting systems and dashboard displays

-

📡 Infotainment and smart connectivity modules

This shift requires PCBs that are thermally stable, vibration-resistant, and built for long life cycles in demanding environments.

2. BaiShun’s Capabilities for Automotive Applications

BaiShun PCB supports the automotive industry with full-stack PCB manufacturing capabilities, from rapid prototyping to mass production.

Key Capabilities:

-

✅ Up to 32 layers for complex control systems

-

✅ 6oz heavy copper for power delivery in EVs

-

✅ 0.15mm BGA pad support for advanced chipsets

-

✅ Impedance control ±7.5%

-

✅ +0.1 / –0.05mm outline tolerance

-

✅ Compliance with RoHS and ISO 9001/14001

We manufacture both rigid and flexible PCBs, making us a one-stop solution for modern automotive needs.

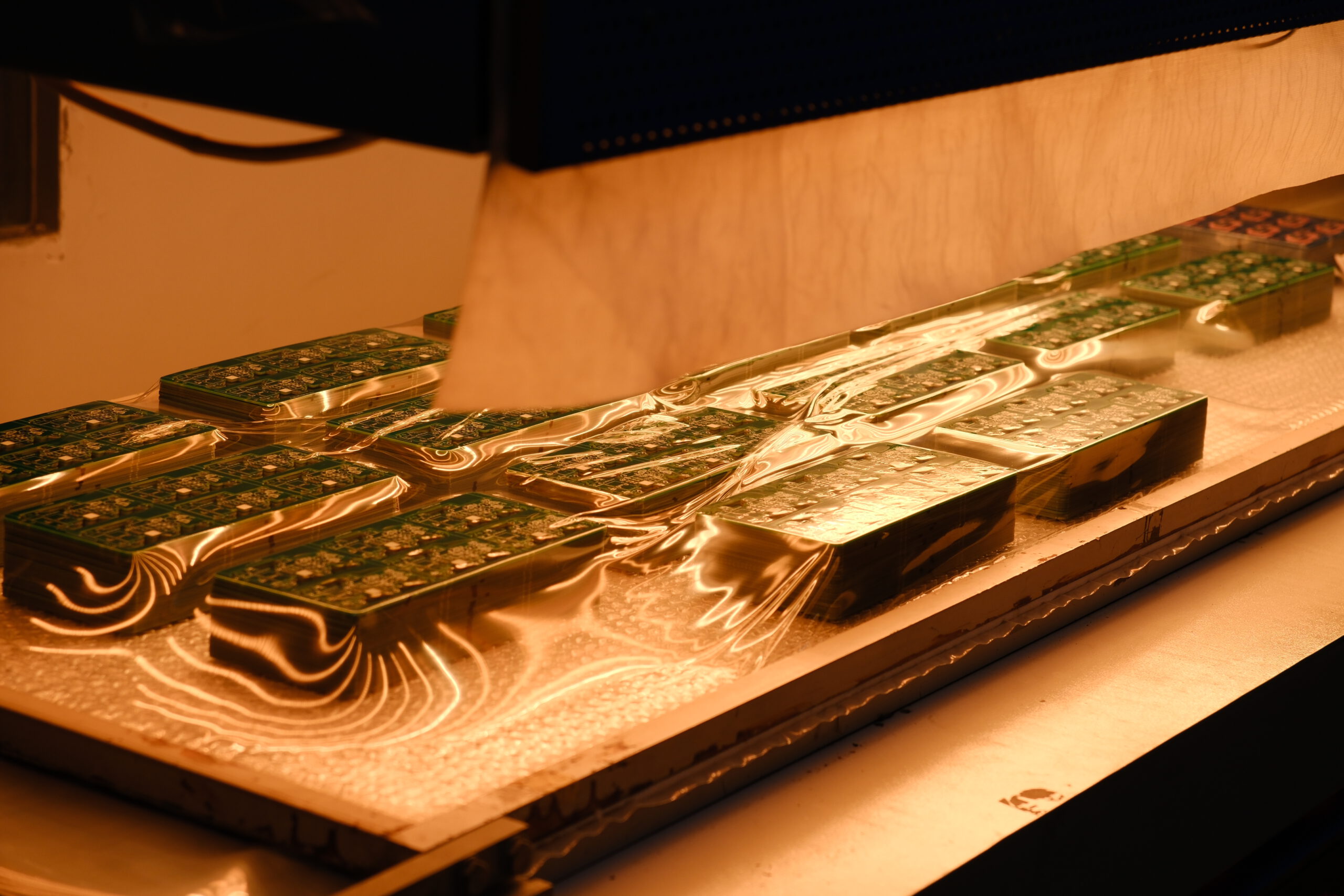

3. EV-Ready: Power Meets Precision

As electric vehicles become mainstream, manufacturers face new challenges: heat dissipation, voltage isolation, and high-current load handling.

BaiShun’s heavy copper PCBs and multi-layer EV control boards are tailored for:

-

🔌 DC-DC converter circuits

-

🧩 Battery management systems (BMS)

-

🧠 Centralized vehicle control units

-

⚡ On-board charging systems

With 6oz copper support, we ensure efficient power flow and thermal reliability across your EV powertrain.

4. Built for Harsh Automotive Environments

Automotive electronics need to function reliably across wide temperature ranges, vibration, humidity, and EMI exposure.

That’s why BaiShun PCBs are built with:

-

🔍 Tight drill tolerances and plating control

-

🧪 In-house surface finishing (ENIG, OSP, HASL, Immersion Tin)

-

🌡️ Materials suitable for -40°C to +150°C operation

-

⚙️ Full electrical testing up to 12,000 test points

Your product might live under the hood or behind a dashboard — either way, we build it to last.

5. Custom Support for Automotive Clients

Our 400+ person technical team includes experienced engineers who understand automotive standards and can assist with:

-

📐 Stack-up optimization for EMI/thermal control

-

🧾 Material selection based on durability + cost

-

🛠️ Prototype-to-production scale-up

-

🔁 Flexible lead times and logistics support

From EV startups to Tier 1 auto suppliers, BaiShun supports projects with flexibility, speed, and full factory control.

✅ Conclusion

The automotive world is moving fast — and your PCB supplier should, too. At BaiShun PCB, we combine high-reliability manufacturing with deep technical experience to support every phase of your automotive project.

If you’re designing for EVs, control units, or next-gen automotive systems, let’s build it together — with precision, speed, and confidence.

📎 Need a quote for your automotive PCB project?

👉 [Click here to upload your Gerber files] or email: hello@jxbsdlkj.com