30,000 m²

Factory Size

800,000 m²

Annual Capacity

14 Years

PCB Dedications

400+

Skilled Technicians

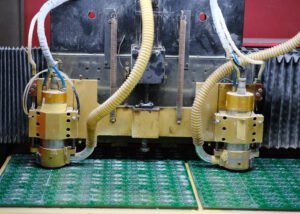

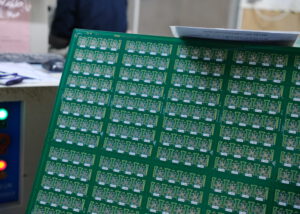

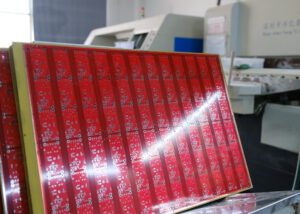

Explore our State-of-the-Art Manufacturing Facility

Providing Best Solutions of Every Kind

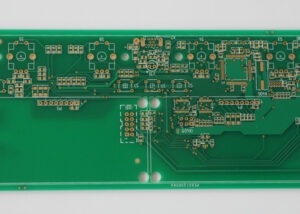

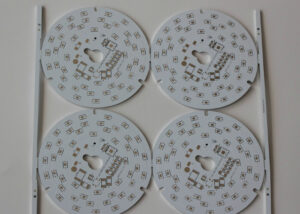

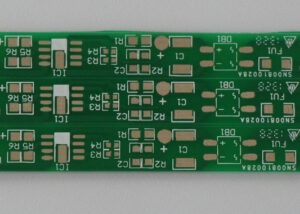

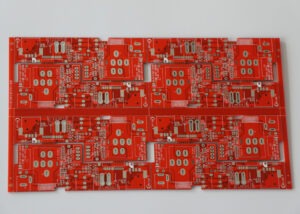

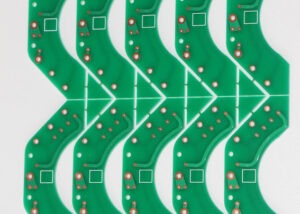

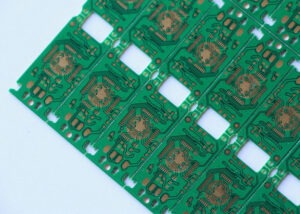

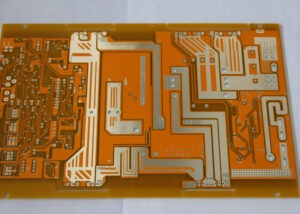

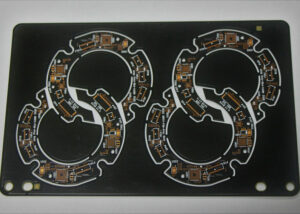

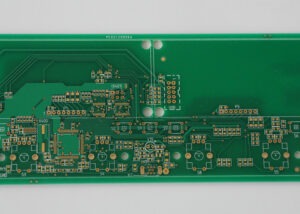

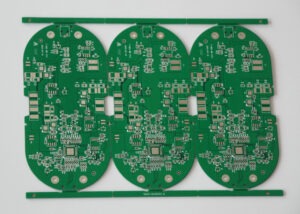

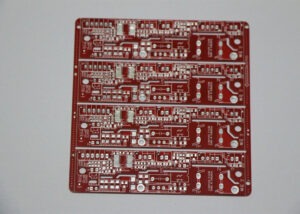

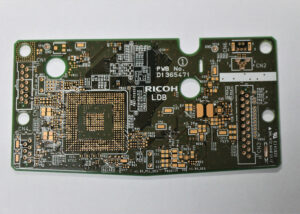

From everyday electronics to mission-critical systems, we manufacture a full range of high-performance PCBs — including Power Supply, Industrial Control, Automotive, Communication, Medical, and Military applications. With deep industry experience and flexible production capabilities, BS PCB delivers tailored solutions to meet the unique demands of every sector we serve.

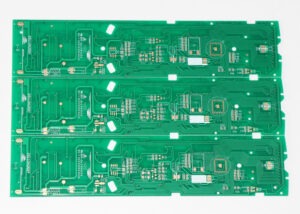

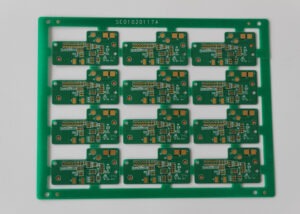

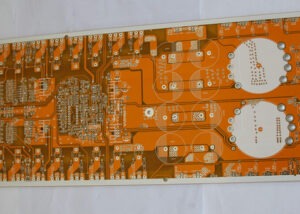

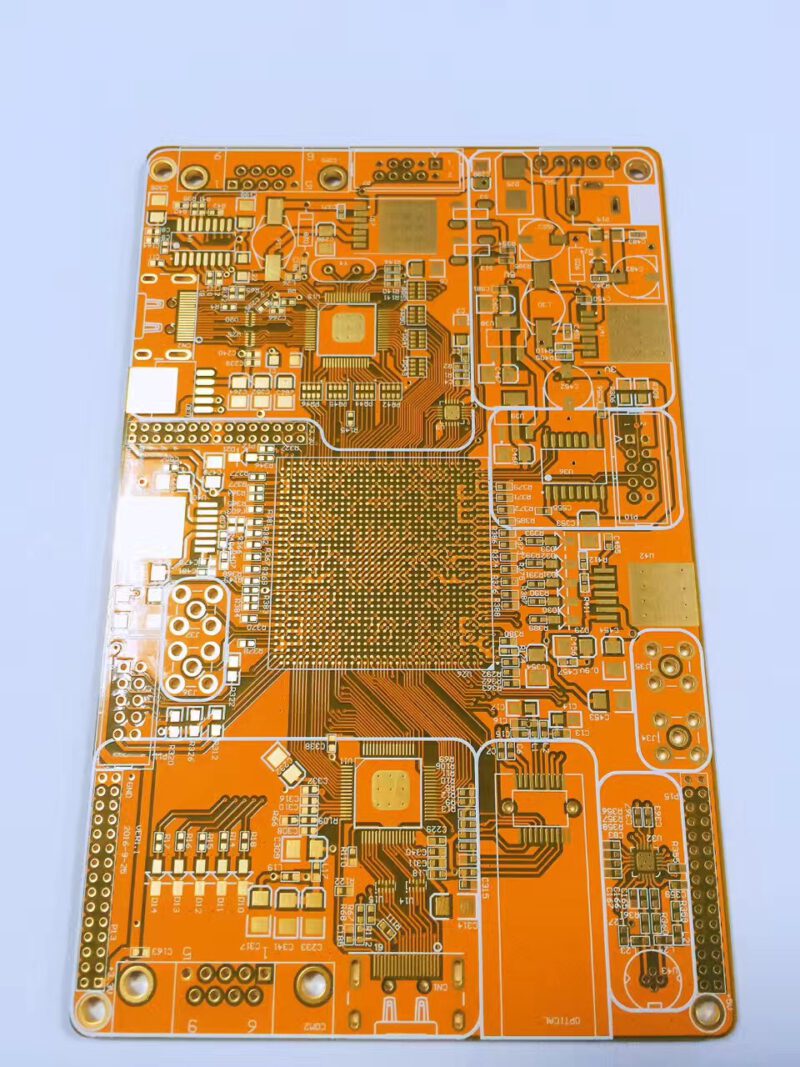

Manufacturing Capabilities

Our factory delivers advanced PCB manufacturing with up to 32 layers, 2.5 mil trace/space, and 6oz copper for high-current designs. With full in-house surface finishing and tight tolerances, we meet the needs of high-reliability industries—and we’re ready to customize for your most specific technical requirements.

| Capability Item | Phase 1 (Issue 1) | Phase 2 (Issue 2) |

|---|---|---|

| Max Layer Count | 12 layers | 32 layers |

| Board Thickness | 0.4 – 3.0 mm | 0.3 – 3.2 mm |

| Max Panel Size | 20″ × 22″ | 22″ × 24″ |

| Copper Thickness | 0.5oz – 3oz | 1/3oz – 6oz |

| Drill Hole Size | 0.25 – 6.50 mm | 0.20 – 6.50 mm |

| Hole Tolerance (PTH) | ±0.08 mm | ±0.05 mm |

| Hole Tolerance (NPTH) | ±0.05 mm | +0 / –0.05 mm |

| Hole Tolerance (Slot) | ±0.10 mm | ±0.08 mm |

| Max Aspect Ratio | 1:6 | 1:8 |

| Outline Tolerance | ±0.1 mm | +0.1 / –0.05 mm |

| VCUT Angle | 20° / 30° | 20° / 30° / 45° / 60° |

| Min Trace / Space | 3 / 3 mil | 2.5 / 2.5 mil |

| Min BGA Pad | 0.27 mm | 0.15 mm |

| Impedance Tolerance | ±10% | ±7.5% |

| Surface Finishing | HASL, ENIG, OSP, ENIG+OSP | + Immersion Tin, Hard Gold, Plating Gold, Carbon Ink |

| Warp & Bending Tolerance | ≤ 0.75% | ≤ 0.5% |

| E-Test Points | ≤ 8000 points | ≤ 12000 points |

Why do so many choose BS PCB ?

Trusted by Global Customers

We’re a factory—not a broker—delivering direct pricing, consistent quality, and fast turnaround, trusted by clients worldwide across multiple industries.

Premium Raw Materials from Global Brands

We use A-grade imported materials from trusted suppliers:

-

Substrates: TUC, Isola, Rogers, Arlon, Hitachi, Taconic, Nelco

-

Chemicals & Ink: Rohm & Haas (US), Atotech (Germany), Taiyo (Japan), Dupont (US)

This ensures stable quality at the source.

In-House Surface Finishing Capabilities

BaiShun is among the few PCB manufacturers with a full suite of surface treatment equipment.

We support: ENIG, ENEPIG, OSP, HASL, Immersion Silver/Tin, Hard Gold, and more — covering the diverse needs of medical, telecom, automotive, and military sectors.

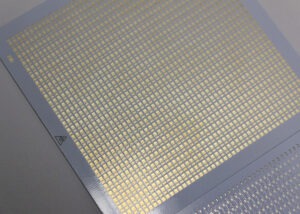

Advanced Manufacturing Capability

We support complex, high-precision boards with:

-

Up to 32 layers

-

6oz copper thickness

-

0.075mm line width/spacing

-

22” × 24” max panel size

-

Hole size: 0.25–6.5mm, tolerance ±0.05mm

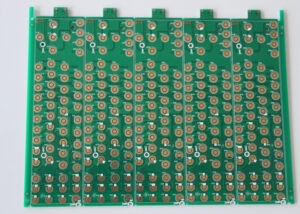

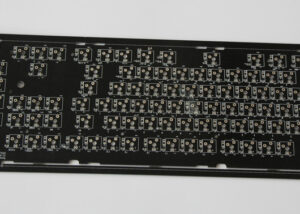

Rigid Quality Control System

Every board is built under strict IPC standards, with:

-

100% yield inspection before shipping

-

Ongoing PDCA cycle for quality optimization

-

AOI, flying probe, and high-reliability testing systems to ensure performance in demanding environments

Certified & Eco-Friendly Factory

We are a national high-tech enterprise recognized for:

-

Green PCB manufacturing leadership

-

ISO, RoHS, and Clean Production certifications

-

Titles such as “Green Manufacturing Pioneer” and “Waste Reduction Advanced Enterprise”